AEROSOL EUROPE is the leading medium for the international aerosol industry. It is written by experts for experts. The entire range of topics relating to the industry is covered, supplemented by company profiles and interviews with leading industry personalities. Topics relevant to the global aerosol market, individual products and companies and fairs and congresses are discussed in detail.

DESPRAY Environmental, a global leader in aerosol recycling technology, has announced a strategic partnership with Nigeria-based FREEE Recycle Limited to introduce the innovative "Food Fuel" project. This collaboration will deploy DESPRAY's state-of-the-art systems to recover and purify propellant gases from aerosol cans, converting them into affordable, clean cooking fuel. The initiative aims to address Nigeria's—and broader Africa's—household air pollution crisis by providing a sustainable alternative to harmful traditional fuels.

The partnership was formalized through a Memorandum of Understanding (MOU) signed at DESPRAY's headquarters in Almelo, The Netherlands. Key representatives included Eelco Osse, CEO of DESPRAY, and Ifedolapo Runsewe, Founder and Managing Director of FREEE Recycle Limited, government officials of The Netherlands and the government officials of Nigeria.

The "Food Fuel" concept was pioneered by DESPRAY Co-founder and Managing Director Mike MacKay. In 2018, while on a family vacation, MacKay encountered a news article highlighting the widespread use of contaminated, cancer-causing cooking fuels in Africa due to limited access to clean alternatives. Recognizing an opportunity, MacKay envisioned repurposing aerosol propellants—often viewed as waste—into a viable cooking fuel solution. A casual Facebook post about the idea went viral, garnering over 2 million likes in just two days, validating the potential for global impact.

Six years later, this vision is becoming reality. "Food Fuel" leverages one recycling byproduct to solve a pressing public health issue, aligning with circular economy principles central to the aerosol industry.

FREEE Recycle will operate DESPRAY's DS5000 aerosol recycling system, a containerized unit capable of processing up to 10 million aerosol cans annually. The system achieves 100% recovery of metals, liquids, and propellants, with DESPRAY's patented gas purification technology ensuring the reclaimed gases—primarily propane and butane—meet "end-of-waste" standards. A single DS5000 unit can produce up to 200,000 liters of purified gas per year, sufficient to supply clean cooking fuel to thousands of households.

The Freee project involves:

Collection and Processing: Aerosol cans are safely deconstructed in an ATEX/CE -compliant environment with 29 integrated safety features.

Gas Recovery and Purification: Propellants are captured, liquefied, and cleaned to remove impurities, enabling safe repackaging for household use.

Distribution: The resulting "Food Fuel" will be distributed as an affordable, low-emission alternative to traditional biomass fuels.

This technology not only diverts waste from landfills but also supports the aerosol industry's push toward zero-waste solutions, reducing the environmental footprint of the estimated 16 billion aerosol cans discarded globally each year.

READ MOREHousehold air pollution from inefficient cookstoves claims approximately 700,000 lives annually in Africa and 3.2 million worldwide, per World Health Organization data

(https://www.who.int/news-room/fact-sheets/detail/household-air-pollution-and-health). In sub-Saharan Africa, over 900 million people depend on polluting fuels like wood, charcoal, dung, or crop waste, exacerbating deforestation at a rate of 1.3 million hectares per year (Boston College: https://www.bc.edu/bc-web/bcnews/nation-world-society/international/air-pollution-in-africa.html).

The "Food Fuel" project directly tackles these challenges, promoting United Nations Sustainable Development Goals (SDGs) including SDG 3 (Good Health and Well-Being), SDG 7 (Affordable and Clean Energy), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action). By reducing reliance on biomass, it also mitigates greenhouse gas emissions and fosters job creation in waste management and distribution.

The partnership stemmed from a serendipitous encounter at IFAT 2024 in Munich, where Runsewe approached MacKay during booth teardown, sparking a discussion that evolved into this transformative collaboration.

"It’s remarkable how a chance meeting can evolve into a project with such profound potential," said Mike MacKay, Co-founder and Managing Director of DESPRAY. "We're turning aerosol waste into a lifeline for healthier communities."

Eelco Osse, CEO of DESPRAY, commented, "This initiative combines cutting-edge technology with humanitarian impact, delivering scalable solutions that benefit both people and the planet."

Ifedolapo Runsewe, Founder and Managing Director of FREEE Recycle Limited, added, "Partnering with DESPRAY enhances our waste-to-resource strategy, enabling us to build healthier homes, cut emissions, and drive economic growth in Nigeria. This partnership addresses the urgent challenges of hazardous waste in Africa by integrating Desprays’ unique technology into our operations."

The full-scale pilot will launch in early 2027 in Ibadan, Nigeria, with modular community units rolling out in 2028. Expansion across Africa and other regions facing similar fuel challenges is planned thereafter. DESPRAY and FREEE Recycle invite governments, investors, NGOs, and communities to join in accelerating adoption. For inquiries, contact Mike MacKay at mike@despray.com.

In August, thyssenkrupp Rasselstein launched a new international advertising campaign to strengthen its brand perception, which will be seen in trade media and at trade fairs such as Metpack 2026 in Essen. Under the claim “rasselstein® Material matters,” Germany’s only tinplate manufacturer puts the focus – using striking color accents and a clear visual language – on the products made from packaging steel: food cans, paint and aerosol cans, and crown corks. The particular strengths of rasselstein® tinplate are illustrated by four motifs: premium quality, innovative strength, employee expertise, and the closed material cycle. The series is complemented by a fifth motif that strikingly highlights the advantages of packaging steel over multilayers cartons. On each motif, appropriate symbols are embossed into the cans or crown corks, while the interior is turned outward to reveal the contents. The typical fill product becomes visible – for example, corn in the food can. The new claim replaces the previous tagline “rasselstein® – for those who can!”. The visual execution gets the message across: Quality leaves its mark. “The market has evolved, so it was time to adapt our campaign,” says Carmen Tschage, Head of Communications and Market Development at thyssenkrupp Rasselstein GmbH. “The new campaign shows that behind each of our products there is not only high-quality material but also the expertise of our employees. This interplay is crucial for our customers.”

READ MOREThe advertising campaign is aimed not only at existing tinplate customers but also at fillers who must choose between materials such as glass, plastic, or tinplate when selecting their packaging. thyssenkrupp Rasselstein remains the right partner here, because especially for complex products such as tinplate, in addition to material quality, technical consulting is a central decision criterion.

“We are one of the leading partners for all experts who know exactly what counts in packaging. With the expertise of our employees and thanks to the high efficiency of our innovative packaging steel grades, we find a reliable solution for every requirement of our customers,” says Carmen Tschage.

In addition to placement in trade media, the campaign will in future also be used for trade fair appearances, for example at Metpack 2026 in Essen. “However, the campaign not only strengthens awareness among our customers, but also identification internally. It shows what we stand for – top material quality, reliable service, and a clear stance on sustainability,” summarizes Carmen Tschage. Tinplate features a closed material cycle and a recycling rate of over 80 percent in Europe. It can be recycled again and again without any loss of quality. This makes it ideal for a functioning circular economy and keeps it among the highest-quality packaging materials on the market.

Expansion Underscores Commitment to Robust, Flexible Local Supply Chains

Summit Packaging Systems is proud to announce the official opening of its newest production facility in Toluca, Mexico, marking a significant milestone in the company’s ongoing commitment to strengthening and localizing its global supply chain network.

Investing in Local Excellence

On August 7, 2025, one year after the initial site search began, Summit Packaging Systems celebrated the inauguration of its state-of-the-art, 3,500-square-meter Toluca facility. The new site has two advanced high-speed valve assembly lines, offering an impressive annual capacity of approximately 250 million units, based on a standard five-day work week. A local team of 15 production and seven administrative staff have been training within the global factory network to ensure the same level of quality and service for the Mexican market.

Building a Flexible and Robust Supply Chain

Aligned with Summit’s vertical integration model, the Toluca facility is a pivotal step towards bringing the supply chain closer to its customers. While the site will initially be supported with components from Summit’s global headquarters, the long-term vision is to expand local production. This approach will ensure greater flexibility, minimize potential supply disruptions, and reduce costs—key factors in today’s dynamic global market.

Strengthening Local Partnerships

Summit Packaging Systems is committed to expanding its relationships with global and local aerosol fillers. The focus for the Toluca site is to serve the needs of the domestic market. By investing in local resources, Summit aims to offer customers a more responsive and adaptive supply chain, tailored to the region’s growing demand.

Global Standards, Local Impact

The new facility operates under stringent ISO and BRC quality standards, reflecting Summit’s dedication to delivering top-tier products and services. As the company’s eighth production site worldwide, the Toluca plant is part of a global network that now boasts over 1,000 employees and more than 100,000 square meters of production floorspace.

Leadership and Expertise

Arturo Morales was appointed as General Manager for the facility, bringing with him 23 years of experience—primarily in production, quality, and engineering—at Crown Beverage. His leadership will be instrumental in driving operational excellence and fostering a culture of innovation and quality.

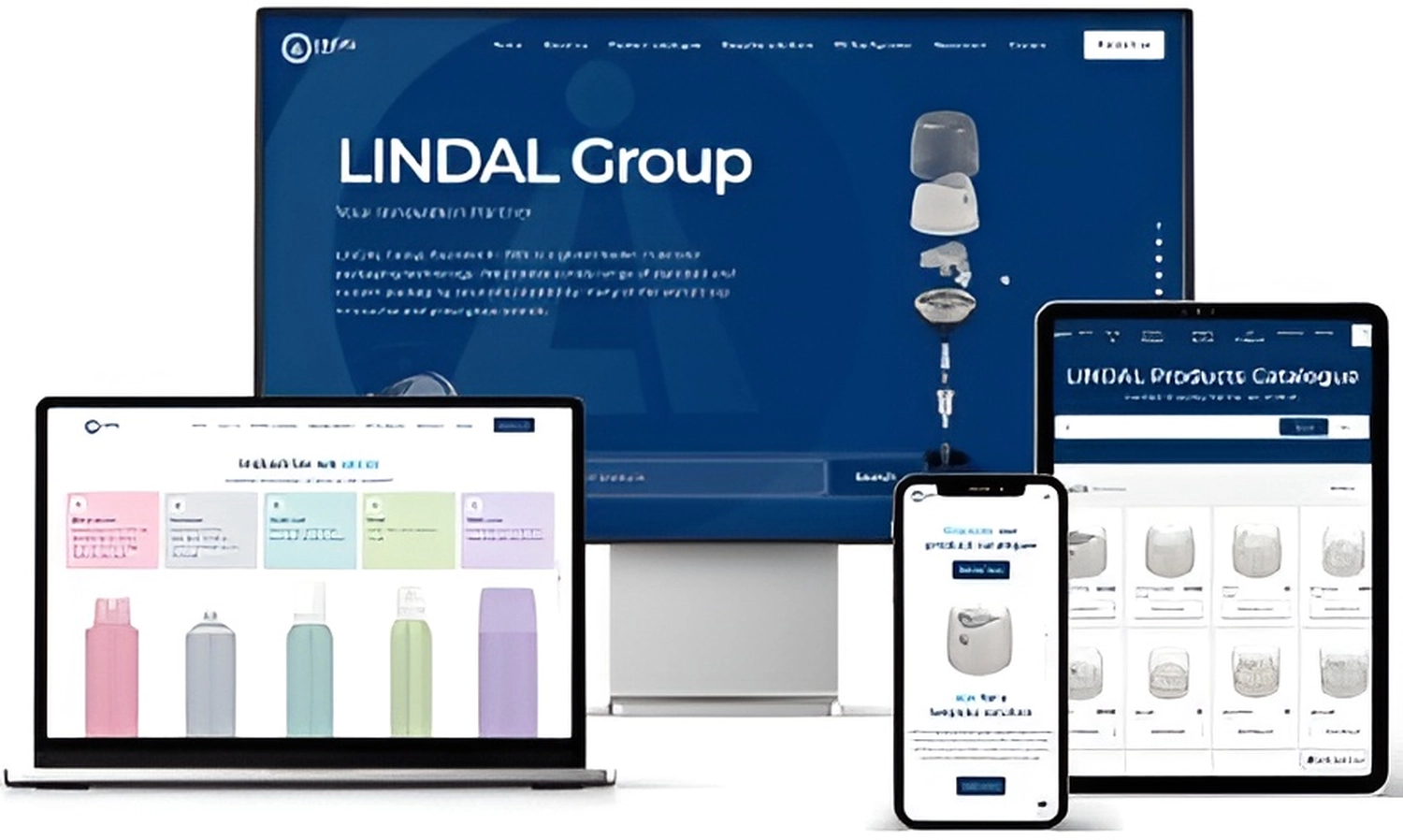

LINDAL Group is proud to announce the launch of its newly redesigned website. Featuring innovative tools, a new contemporary design and enhanced usability, the platform reinforces LINDAL’s commitment to innovation and customer service.

Building on the success of its colour-coded market segment system launched in 2019, the new website simplifies communication with LINDAL’s customers and better engages its audience through innovative design and functionality.

An intuitive search tool allows both expert and non-expert users to find the right product quickly, while customers seeking tailored products or turnkey solutions, are served a balanced showcase of both the existing portfolio and LINDAL’s innovation capabilities.

“Our goal was to create a digital platform that truly reflects who we are as a company — innovative, customer-focused, and future-oriented,” said Kashif Choudhry, Group Marketing Manager at LINDAL Group. “We wanted to not only offer our customers and partners an engaging, and informative experience with seamless access to our products, but to inspire collaboration and discovery across the aerosol industry.”

Redefining the Product Discovery Experience

The new product catalogue allows expert users to refine their search using URS (User Requirement Specifications), for a more precise product selection process. For non-expert users, the new digital assistant provides an intuitive, step-by-step guide to help identify the right solution in less than a minute. The virtual assistant can also be used to contact LINDAL’s Technical Support team.

Each product page has been upgraded to deliver a more interactive experience; allowing users to request product samples for evaluation or connect with the Commercial team to obtain a quotation — simplifying the path from exploration to collaboration.

Introduced in 2021 as an industry pioneer, the 3D Configurator now seamlessly integrates into the platform, enabling users to explore LINDAL’s full product catalogue in 3D, visualise various insert options, and customise actuator colours effortlessly, without creating an account. In just a few clicks, users can also add a can and label to build a complete aerosol package, and easily share their creations by setting up a Configurator account.

Future developments for an evolving global audience

In addition, LINDAL is developing a dedicated page explaining how aerosols work and outlining the fundamentals of aerosol technology. Designed for those new to the industry — or for anyone seeking a quick refresher — this educational resource will soon be available to help users gain a deeper understanding of the technology behind every LINDAL solution.

Further enhancements include a new section on LINDAL’s Sustainability approach, multilingual site versions and a comprehensive Careers section. Continuous SEO improvements will ensure LINDAL remains highly visible to anyone in the aerosol industry, reinforcing its position as a trusted and forward-thinking partner.

“The new website a key milestone in strengthening customer engagement, expanding our digital services, and demonstrates how innovation at LINDAL goes beyond the products — it defines our culture, our services, and the way we work.”

Discover the new website at www.lindalgroup.com